- Active Alignment System

AA equipment (Active Alignment) can adjust the attitude and relative position between lens and image sensor to ensure the clearest center of picture and uniform clarity of four corners of picture, effectively improve the consistency of the camera products, and ensure the quality of the camera.

- Application

-

Notebook PC Camera

-

Smart Phone Camera

-

Tablet Camera

-

Action Camera

-

Drone Camera

-

Automotive Camera

-

Security Camera

-

AR/VR Camera

-

Smart Home Camera

- Related Products

AA2I-DC-G2 Dual Camera AA Assembly System

AA2I-DC-G2

Dual Camera AA Assembly System

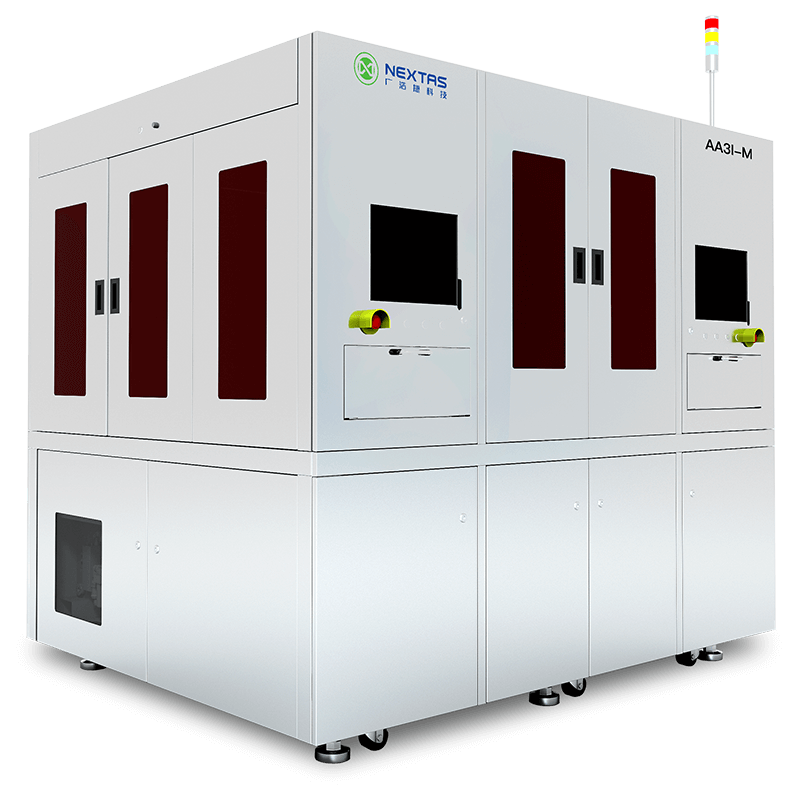

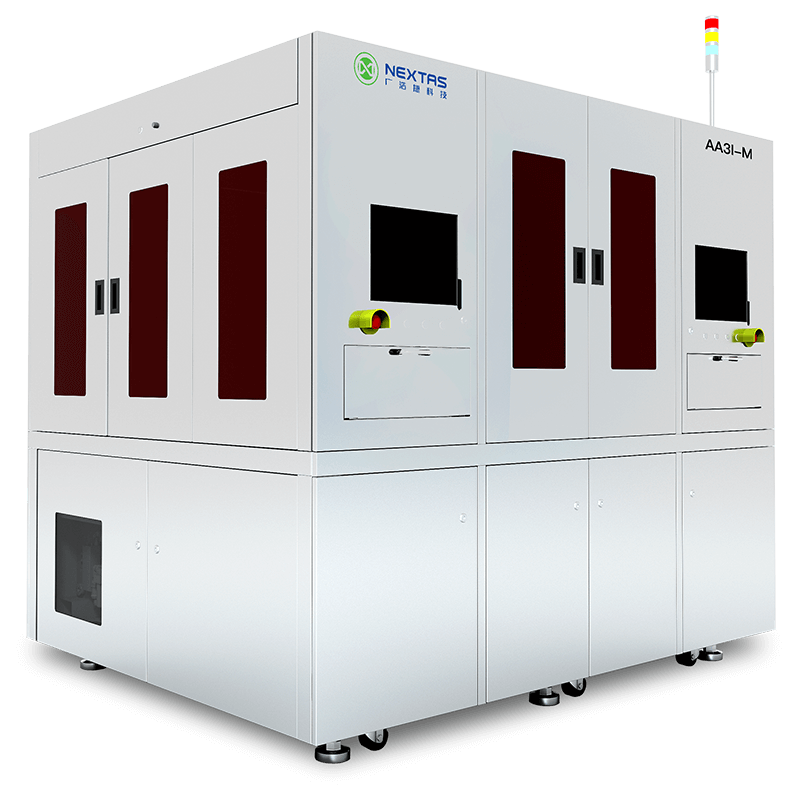

AA3I-M 3-Up Active Alignment System

AA3I-M

3-Up Active Alignment System

AA1A-W Single Station Wide-Angle AA System

AA1A-W

Single Station Wide-Angle AA System

AA4A-W 4-Index Station Wide Angle AA System

AA4A-W

4-Index Station Wide Angle AA System

AA2I-DC-G2 Dual Camera AA Assembly System

FUNCTION

- Build-in with O/S & Electrical test

- AA test is based on the alignment of the relative optical axis of dual camera including baseline spacing adjustment

- Automated Adhesive dispensing & glue cleaning

- UV curing

- Final Test measurement

- Integrated with Automated Pick & Place System

FEATURE

- Design with 2 parallel AA test head system for higher efficiency

- Comply to Class 100 Environment

- High-speed motion mechanism

- Using advance 3D modeling algorithms to compensate lens distortion error

- Intelligent AI dispensing system, defect detection rate up to 99.9%

- Advance Automated Test Socket design

- Auto Pick & Place (APP) Handling System, full-automation production

- Great Uniformity backlight panel design

- Camera interface supports for MIPI-4 and USB3.0

APPLICATION

Dual Camera Module Assembly